About Raw Materials

We use various types of raw materials, such as fiber, powder, and nonwoven fabric, to manufacture products.

Fibers

We use a wide variety of fibers from plants, animals, regenerated, synthetic, and inorganic. Combining more than one type of fiber creates a product that makes the most of the characteristics of each fiber.

Powders

We use several hundred different types of powder. Settling the powders in paper in a very specific method enables the manufacture of paper products in which the characteristics unique to the powders are best used. Powder can be classified roughly into two categories: organic powder and inorganic powder. In this section, let us introduce inorganic powders.

Nonwoven Fabrics

We use various kinds of nonwoven fabrics, such as wet-type, dry-type, and multi-layer nonwoven fabrics. Layering these different sheets by processing enables to create a product that has a specific performance.

Plant Fibers

Plant fibers come from plants, and the plant fibers are processed for use in papermaking from pulp.

Pulp consists mainly of cellulose and is roughly categorized into two types: wood pulp and non-wood pulp.

Wood Pulp

Wood pulp is made from wood fibers from the xylem of wood. Wood pulp is roughly categorized into two types: needle leaf (softwood) and broad leaf (hardwood). Softwoods include the fir and pine tree families, and hardwood include eucalyptus, beech, birch, maple, willow, and rose apple families. In general, softwood tend to have long fibers, and the products made from long fibers tend to be stronger than those made from short fibers. Regarding the wood materials used in papermaking industry as raw material, due consideration is given to the global environment because waste needle leaf tree materials from lumbermills are utilized in a large portion and broad-leaf trees are planted in a systematic manner as tree-planting business.

Non-wood Pulp

Non-wood pulp is made from seed fibers from vegetable seeds as well as bast fibers contained in the peel or stem. They have received a lot of attention as environmentally friendly materials and are available in the following types: cotton linter pulp made from linter (short fibers attached to cotton seed), hemp pulp (it can be categorized into several types depending on the type, characteristics and production area), bagasse pulp made from sugar cane trash, and kenaf pulp made from kenaf (a malvaceae).

Animal Fibers

Animal fibers are fibers from animals and consist mainly of protein. They contain not only silk fiber from silkworms and fur fiber from sheep wool but also collagen fiber extracted from animal skins, chitin from crustaceans, and shellfish like shrimp and chitosan made by deacetylating chitin.

Silk Fiber

Silk fiber is made from silkworm cocoons. The fiber has superior moisture-absorption and desorption property, heat retention property, and staining property.

Sheep Wool

Sheep wool has superior heat insulation and heat retention properties.

Regenerated Fibers

Regenerated fiber is created by dissolving the cellulose area of plant fiber in chemicals and making it into fiber again (by viscose method). Since it consists of cellulose like cotton and hemp, it is also called "regenerated cellulose fiber."

Rayon (Viscose, Staple Fiber)

Rayon is created by dissolving the cellulose area of wood pulp in chemicals and making it into fiber again (viscose method). It consists of cellulose like cotton and hemp.

On etymological grounds, rayon is also called artificial silk because it is shiny ray with gloss like silk. It is characterized by smooth texture, unique gloss, moisture absorption and desorption properties and superior staining property. It is used widely because it does not get soft and melt with heat.

Synthetic Fibers

Synthetic fibers are made from organic synthetic high-molecular compounds and are made synthetically from raw materials such as petroleum oil. Using this fiber alone or mixing it with natural pulp provides products with the useful characteristics of fiber.

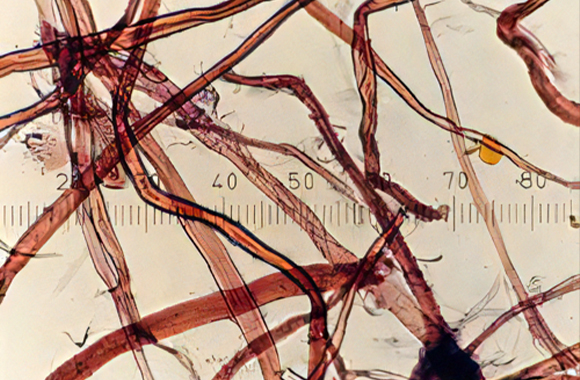

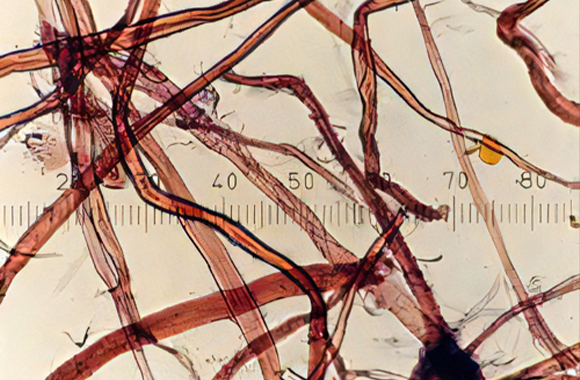

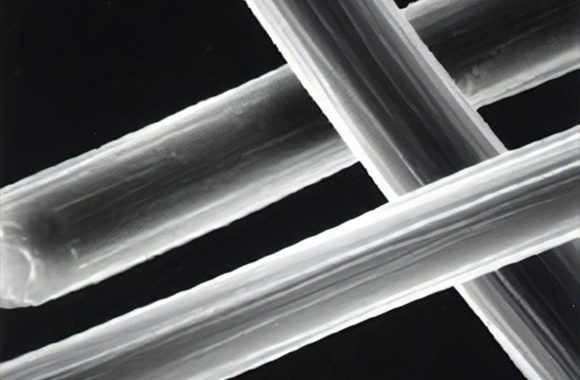

Polyester Fiber (PET Fiber)

Polyester fiber is manufactured in the largest amount among synthetic fibers and is frequently used for paper. Polyester is a general term for a high molecule with an ester bond structure but refers to polyethylene terephthalate (PET) in the case of fiber.

It is characterized by high strength and superior heat and water resistance. We not only mix this fiber with other raw materials but also offer PURELY made from 100% polyester fiber.

Polyolefin Fiber (Polypropylene Fiber, Polyethylene Fiber)

Polyolefin fiber is made from hydrocarbon-based high molecules like polypropylene and polyethylene. This material is characterized by extremely light specific gravity lower than 1 (approximately 0.90–0.96) and superior chemical resistance against acid and alkali. In particular, among composite fibers, core-clad fiber (sheath core fiber) whose core is made from polypropylene and clad is made from polyethylene and side-by-side fiber that consists of polypropylene and polyethylene approximately half-and-half are frequently used as thermal fusion bonding fiber. We not only mix this fiber with other raw materials but also offer ALT made from 100% polyolefin fiber.

Acrylic Fiber

Acrylic fiber is a fiber made from polyacrylonitrile and is characterized by heat resistance, dyeability, dimensional stability, and chemical resistance. In addition, aside from acrylic fiber, modacrylic fiber contains only a low proportion of polyacrylonitrile and other raw materials to provide various functions (flame resistance, antimicrobial property and heat retaining property).

Aramid Fiber

Aramid fiber is a fiber whose molecular structure consists of aromatic series and amide linkage and is available in two types: para-aramid and meta-aramid. This fiber is characterized by high strength and modulus of elasticity as well as superior impact, wear, heat and chemical resistance. Therefore, it is frequently used due to its high functionality although it is expensive.

Vinylon Fiber (PVA Fiber)

Vinylon fiber is made from polycinyl alcohol. This fiber is characterized by light resistance, hydrophilic property, and adhesion property and is used in various paper fields.

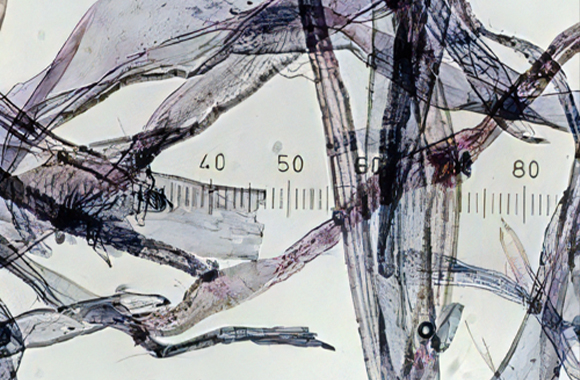

Inorganic Fibers

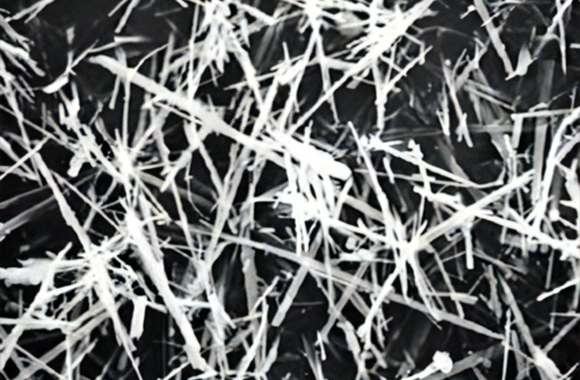

Inorganic fibers are the fibers made from inorganic materials and are classified into the following categories: glass fiber, amorphous fiber like rock wool, carbon fiber, polycrystal fiber like alumina fiber, and monocrystal fiber like wollastonite and potassium titanate fiber. Amorphous fiber is high in strength even though modulus elasticity is low because there is no grain boundary. Polycrystalline fiber has superior heat resistance because it consists of small crystals. Monocrystalline fiber is extremely high in strength because of the whisker-like fine fibers.

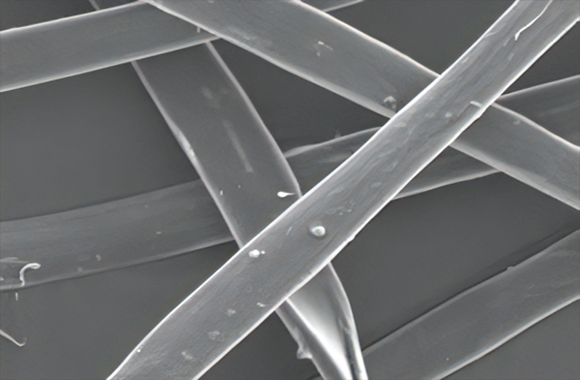

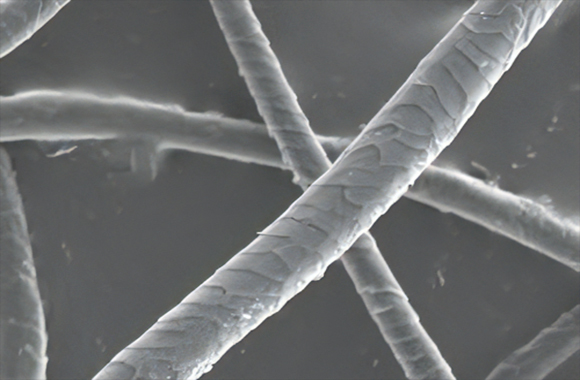

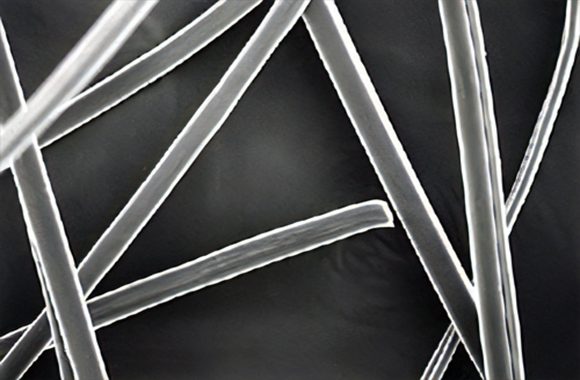

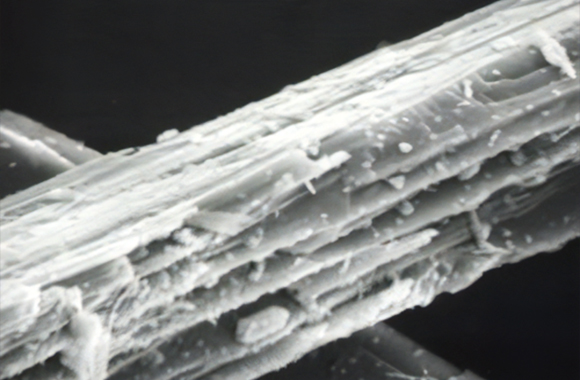

Glass Fiber

The glass fibers mainly used for papermaking are the chopped strands with a fiber diameter of 6–20 µm and a fiber length of 3–25 mm with superior heat resistance and dimension stability. The sheets containing glass fiber are used for floor, insulation, and building materials due to their characteristics.

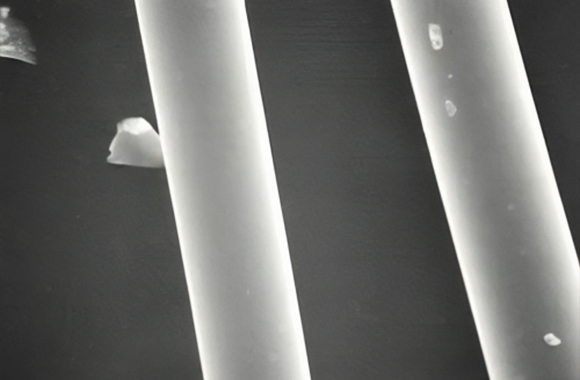

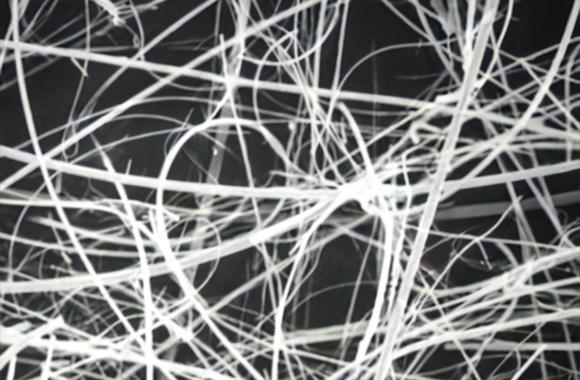

Micro Glass

Micro glass is a wool-like glass fiber with a fiber diameter of 0.1–3 µ. It is used for various types of filters, analytical-grade filter paper, and insulating materials.

Carbon Fiber

Carbon fibers has following two main categories: PAN (polyacrylonitrile)-based type and pitch (petroleum oil and coal)-based type

The fibers are characterized by superior mechanical strength, modulus of elasticity, heat resistance, and chemical resistance. Their electric resistance and heat conductivity are similar to those of metals. Therefore, they are applied to electromagnetic shields, electrodes and heat-resistant structures through the use of their property of low thermal expansion coefficient.

Activated Carbon Fiber

Activated carbon fiber is characterized by excellent absorption rate that cannot be achieved by granules and powders. This fiber is mainly used in filter applications because this fibrous form creates a sheet with low pressure loss.

Meerschaum (Hydrated Magnesium Silicate)

The component of meerschaum is magnesium silicate and is equivalent to talc, but meerschaum has different molecular structure with micro-level fine pores. Since this material is in fibrous form, it is also effective as inorganic binder. This material has a large surface area and superior adsorptive property. Therefore, it is suitable for the adsorption to and deodorization of the substances with small molecular weight and polarity, such as water, ammonia, and hydrogen sulfide.

Potassium Titanate Fiber

Although potassium titanate fibers have needle crystals, it can have different crystal structures depending on the process of manufacture. The physical and chemical properties differ depending on the structure. When the fiber diameter is at submicron level, the strength of fiber is expected to increase significantly. This material is characterized by extremely low heat thermal conductivity and high electrical insulation properties in the high temperature range. Depending on the type of crystal structure, some are chemically active or have positive ion exchange performance. Through the use of such properties, this material is applied to heat and electric insulating materials as well as filters.

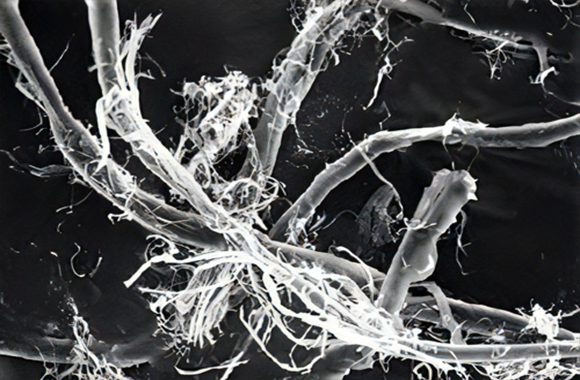

Ceramic Fiber

Ceramic fiber is a general term for artificial inorganic fiber that consists mainly of alumina and silica. Although the removal of granular shots that could not turn into fibers (non-fibrous granule) due to its process of manufacture is a bottleneck, this material is lightweight and flexible with superior heat insulation and resistance properties to withstand temperatures of 1000°C and higher as normal service temperatures. Therefore, it is used for sealing, packing, heat insulating, heat retention materials, and filters.

Wollastonite (Calcium Silicate Fiber)

Wollastonite is a natural mineral developed by being subjected to metamorphism at the point of contact between limestone and granite with a needle-like crystalline body. This material has attracted attention as an alternative to asbestos and has superior heat resistance and electric insulation property.

Rock Wool

Rock wool is created by combining iron-making blast furnace slag with silicate rock, basalt rock and lime rock for the improvement of the fiber property. This material has superior flame resistance, fire resistance, sound absorbing and insulating properties, and is generally used for heat retaining, heat insulating, and sound absorbing materials.

Carbon-based Powders

Carbon-based powders are generated by roast organic substances. The characteristics of carbonaceous materials vary depending on the type of organic substance and manufacturing conditions. This powder has superior adsorption properties for organic substances and excellent properties of thermal conductivity, acid and alkali resistance, solvent resistance, heat resistance, and lubrication. The powders are also characterized by their conductive properties, although they are non-metal and have attracted attention as future materials.

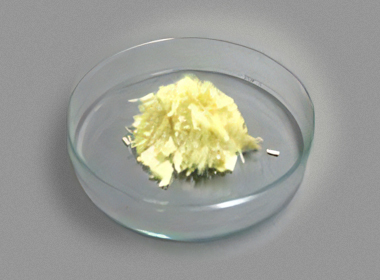

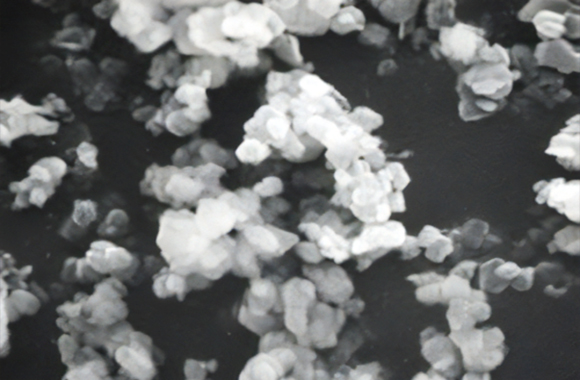

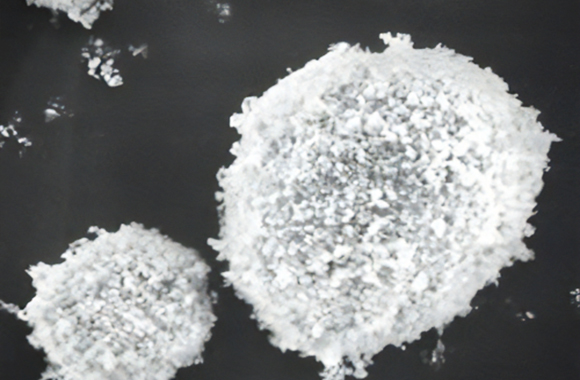

Activated Carbon

With an increased surface area as shown in the figure, activated carbon has higher adsorption and catalyst performance than other carbons. Activated carbon is made from raw materials with a large surface area, such as palm shell, coal, and charcoal, and its adsorption performance depends on the manufacturing conditions. This material in the liquid phase can be applied to the purification of impure substances and catalysts, and the one in the gas phase can be applied to the adsorption of odors and organic gases. Recently, this material is also expected to be applied to the resolution of environmentally hazardous substance materials and VOC.

Charcoal and Bamboo Coal

Charcoal and bamboo coal are renewable botanical resources. They have the adsorption function equivalent to that of activated carbon because the structure as plants remains as a large number of pores even after the burning process. Because the coals with distinctive functions can be created by changing the burning method and temperature, the material will receive more attention in the future.

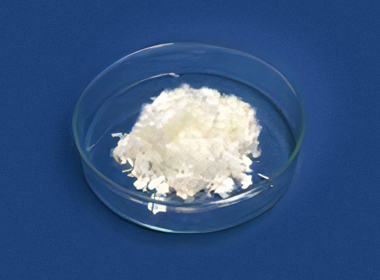

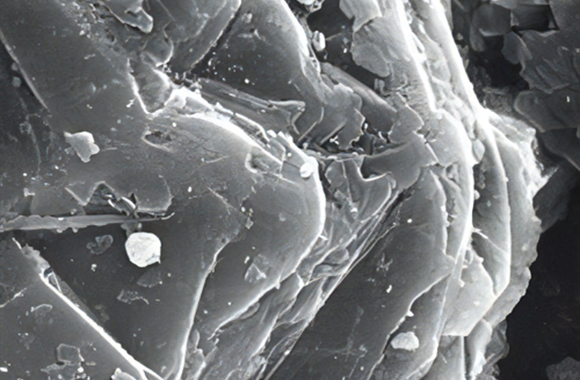

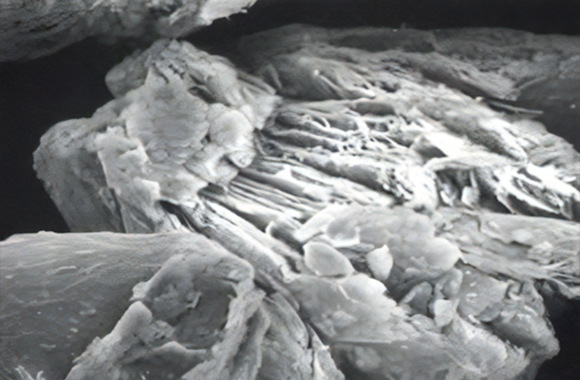

Graphite

Graphite is crystalline, although charcoal and coal are non-crystalline. Carbon has a hexagonal-like structure, and the crystals are shaped like flat scales as shown in the figure. Graphite has especially higher heat conductivity compared to other carbons, and the heat conductivity of highly pure graphite is equivalent to that of aluminum. Due to its structure, this material tends to break easily in the Z-axis direction, which is perpendicular to the hexagonal surface, and has a low friction effect.

Mineral-based Powders

Mineral-based powders can be classified into the following two types: powders based on natural minerals and powders based on artificial minerals manufactured through processing or synthesis. Natural minerals include calcium carbonate, kaolin clay, and talc, and artificial minerals include aluminum hydroxide and potassium titanate. When applied to paper, these materials are added through internal addition (added as a raw material during manufacturing process) or through the methods of size press, impregnation, and coating.

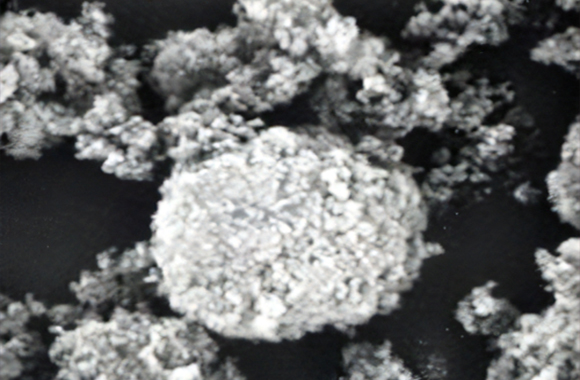

Diatomic Earth

Diatomic earth is ancient diatom fossils and can be classified into the following two types with different shapes: freshwater-based diatoms and seawater-based diatoms. They consist mainly of silica (SiO2) and are used in filters because they are porous as shown in the figure. Filling this material in paper with creates a sheet with low density and a lot of pores.

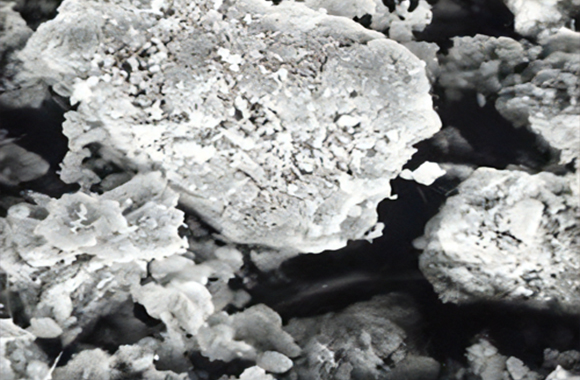

Talc

Talc consists of magnesium silicate, is shaped like hexagonal plates as shown in the figure, and contains crystal water. Also known as talky stone, this material is slippery and is used as an agent for enhancing smoothness. Incorporating this material creates products with high smoothness and heat resistance. Since this material is inexpensive, it is used as a loading material for paper coating.

Calcium Carbonate

Calcium carbonate powder is generally transparent prism-like crystals used in printing paper because it enhances the visual quality of inks. This material has been utilized for coating to enhance the printing performance and as a filling material. Since this material is sensitive to acid, when this material is used as a raw material for paper, a fixing agent in the neutral pH range is used for fixation but not acid fixation using an acid fixing agent such as aluminum sulfate.

Aluminum Hydroxide

Gibbsite has the general molecular structure of aluminum hydroxide. The temperature of decomposition of crystal water is approximately 270°C, and this is similar to the initial combustion temperature of organic materials, such as pulp. Therefore, adding this material to paper for the endoergic reaction at the crystal decomposition temperature creates flame-resistant paper. In addition, since its surface electric charge is cationic, this material is fixed firmly to pulp in the water because it is anionic.

Titanium Oxide

Titanium oxide has been used as an agent to enhance whiteness and concealment and can be classified into the following two types: anatase type and rutile type. The anatase type has a little lower light resistance than the rutile type. Photocatalysts have been covered widely in the media in recent years as a product focusing on light resistance, which is a shortcoming of anatase-type titanium oxide. Photocatalyst-type titanium oxide has the property of decomposing organic materials and is used for environmental purification.

Vermiculite

Vermiculite is produced as altered mica. Through special high-heat processing, vermiculite expands and becomes a material with high porosity and low apparent density. This material is characterized by superior heat resistance, sound absorption, light in weight, moisture adsorption, positive ion exchange performance, wear resistance, acid resistance, and alkali resistance. The sheets are expected to be developed by using such characteristics.

Zeolite

Zeolite is characterized by the property of absorbing polar gases and has excellent water vapor adsorption properties. For this reason, this material is frequently used for desiccants and humidity conditioning for air conditioning. In addition, this is also effective as a deodorant because it absorbs malodorous components like ammonia and sulphureted hydrogen. This material is expected be applied to papers through internal addition to pulp, as well as through secondary processing, such as impregnation and coatings.

White Carbon (Synthetic Silica)

There are two types of silica: natural silica and synthetic silica. Synthetic silica is non-crystalline (amorphous) and has less of an impact on the environment in the exposure status compared to natural silica. Because this material has large specific surface area and low refractive index, it is used for printing papers (ink-jet printing papers) and is effective in showing brilliant colors of ink. In addition, fine-grained silica with large specific surface area is an ideal filtering material.

Wet-type Nonwoven Fabric

Wet-type nonwoven fabric is a nonwoven fabric created through the medium of water and uses shorter synthetic fibers than dry-type nonwoven fabric. In addition, this material allows the mixing of fibers in any proportion irrespective of whether the fibers are natural or synthetic to create uniform sheets.

The optimum processing method is selected depending on the sheet to be combined.

Dry-type Nonwoven Fabric

Dry-type nonwoven fabric is created by web-forming chemical or synthetic fibers with long fibers with a carding machine and providing strength using a needle punch, heat treatment and resin binders. Since this fabric has a texture like cloth, it is frequently used for medical and hygiene products.

The optimum processing method is selected depending on the sheet to be combined.

Bonded Nonwoven Fabric

Through various types of bonding processes, such as thermal fusion bonding, wet lamination, and dry lamination, it is possible to laminate different types of sheets to provide special performance.

The optimum processing method is selected depending on the sheet to be combined.