Collaborative research system

Based on the theme from the customer, we assist in achieving the goal through collaborative research as shown below.

Evaluation

by

customer

- STEP1Determination of development theme

-

Applications,materials used,and required

specifications are determined on the basis of

consultions with the customer.

- STEP2Laboratory experiment

-

The strength and composition of the material

are tested to determine whether it can be

made by hand.

- STEP3Tset paper machine

-

A test paper machine is used to check

suitability for papermakikng with a small

amount of raw materials.

- STEP4Trial production using actual equipment

-

Trial production is performed using a paper

machine for mass production.

An evaluation is performed using a performance evaluation device.

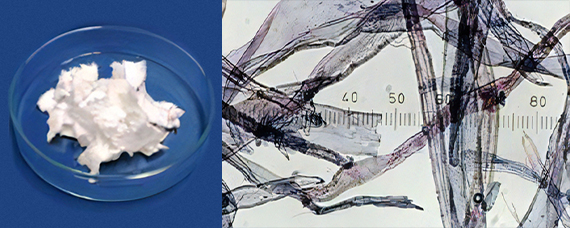

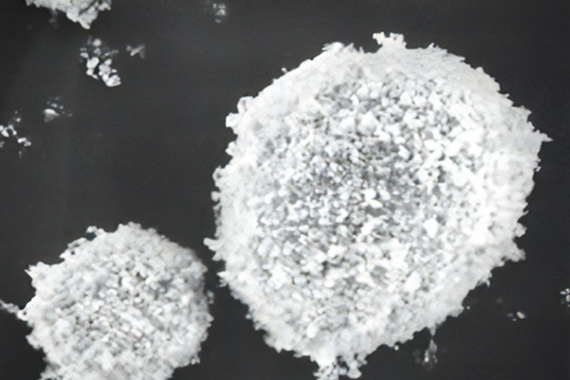

STEP1 Determination of development theme

We use a variety of fibres and powders, including plant, animal, recycled, synthetic and inorganic fibres. By combining several fibres, we can make use of the characteristics of each fibre or make products by loading them with powder.

From the customer's point of view, materials are selected according to the intended use and required performance, and the optimum composition plan is proposed.

Material

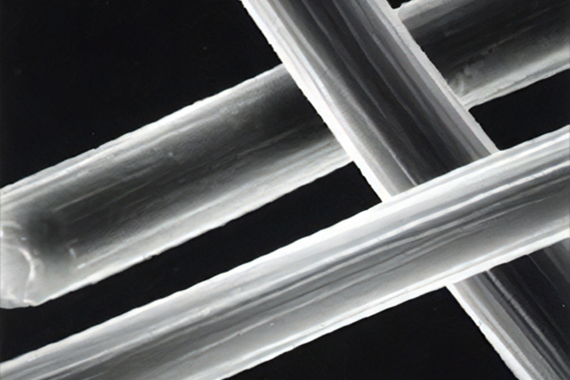

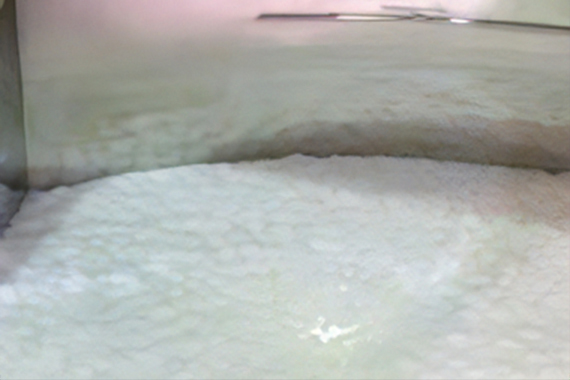

STEP2 Laboratory experiment

Based on the composition plan, we determine the raw material composition and physical properties that satisfy the required performance by actually producing the sheets using various laboratory-scale experimental machines.

Experimental equipment

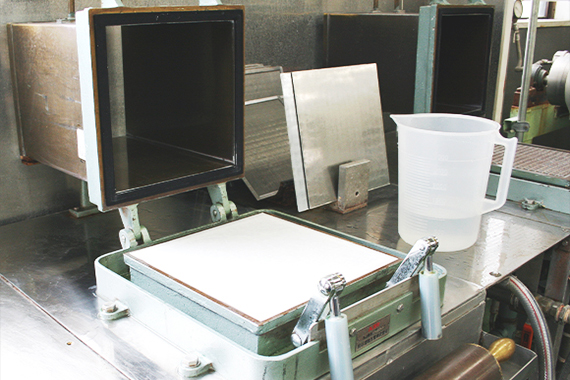

STEP3 Trial production on a test paper machine

Paper is actually made in a roll-to-roll process using a test paper machine capable of making paper from a small amount of raw material, to check whether the designed properties can be obtained and to confirm the correlation with laboratory tests and the suitability of the paper for making paper.

Test paper machine

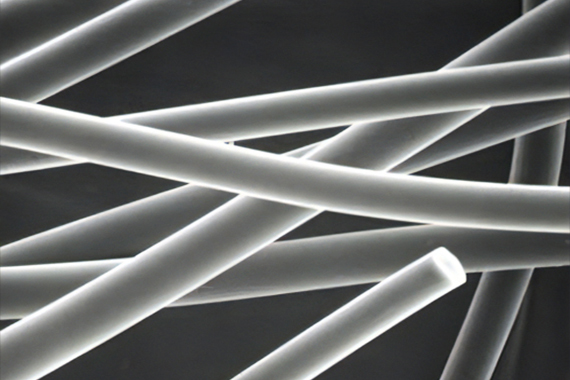

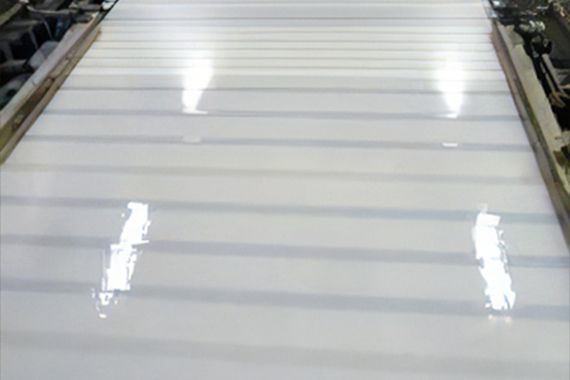

STEP4 Trial production using actual equipment

Paper is actually made by selecting the most suitable paper machine for mass production according to the required properties and performance, to check whether the designed properties can be obtained and to confirm the suitability for mass production.

Mass production facilities

Perfomance evaluation

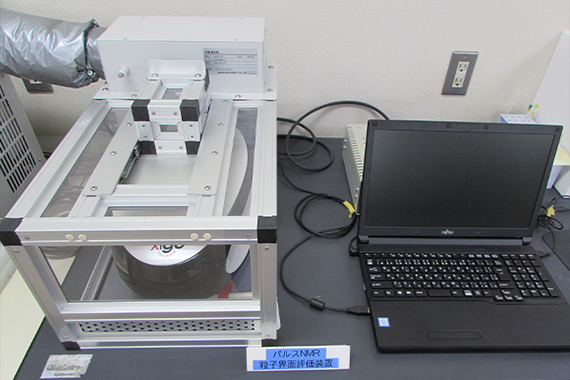

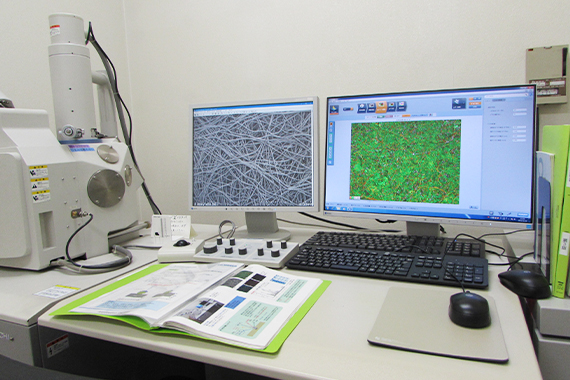

Various evaluation and testing facilities are owned and utilised to check whether the samples actually made into sheets in laboratory experiments, on test paper machines and on trial production on actual machines perform as designed.

Evaluation equipment

Energy dispersive X-ray analyser (EDX)